With the continuous innovation and expansion of Japan's electronics industry, the demand for thermal interface materials (TIMs) in the country is also growing significantly. The TIM market plays a critical role in managing heat in electronic devices to ensure their longevity and optimal performance.

Renowned for its robust technological ecosystem and high-quality manufacturing standards, Japan's market is expected to grow from $261.5 million in 2023 to $740.4 million by 2032, according to forecasts by Report Ocean Co., Ltd. This growth represents a compound annual growth rate (CAGR) of 11.64% from 2024 to 2032, highlighting the industry's immense potential and the expanding applications of TIMs across various sectors.

Market Dynamics

Growth Drivers:

The rapid expansion of Japan's thermal materials market is fueled by the ongoing evolution of electronic devices such as smartphones, laptops, and other household appliances, which require advanced thermal management solutions to keep up with increasing processing power. Additionally, the rise of the automotive industry, particularly electric vehicles (EVs), is a major contributing factor. These vehicles rely on efficient thermal management systems to maintain battery performance and safety, thereby driving demand for high-performance TIMs.

Challenges:

Despite the optimistic outlook, the market faces several hurdles, including the high cost of advanced materials and the technical difficulties of integrating them into existing manufacturing processes. Furthermore, Japan's stringent environmental regulations on the production and disposal of chemical materials pose additional barriers for market players.

Opportunities:

The shift toward renewable energy and the growing adoption of hybrid and electric vehicles are opening new avenues for TIMs. Innovations in material science, offering eco-friendly alternatives with high thermal conductivity, may also create lucrative opportunities for market leaders.

Competitive Landscape

Japan's TIM market is highly competitive, with both domestic and international manufacturers driving growth. Companies are increasing investments in R&D to push the performance boundaries of these materials. Strategic alliances and acquisitions are also common as firms seek to strengthen their product portfolios and expand their market presence.

Technological Advancements

Technological innovation is at the core of the TIM market's expansion in Japan. Recent developments in nanotechnology and the introduction of hybrid materials that combine the thermal conductivity of metals with the flexibility of polymers are poised to revolutionize the industry. These advancements not only enhance the performance of TIMs but also improve their adaptability to high-stress environments in advanced electronics and automotive applications.

Market Segmentation

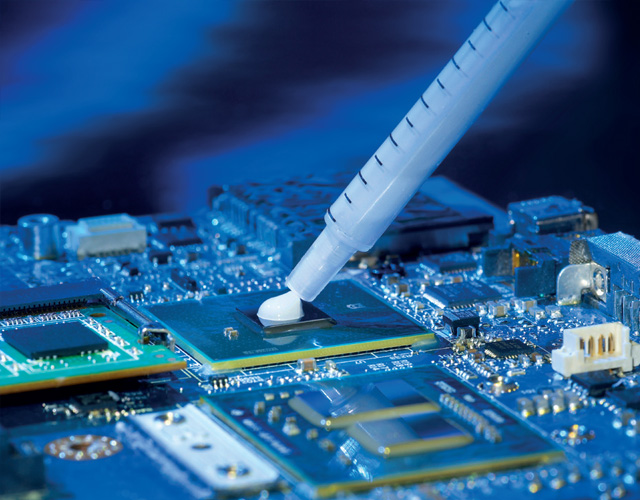

The market can be segmented by type, including greases & adhesives, tapes & films, gap fillers, metal-based TIMs, and others. Each segment addresses specific needs across different applications, with greases and adhesives dominating the market due to their ease of use and thermal management efficiency. Application areas span electronics, automotive, telecommunications, and more, demonstrating the broad utility of TIMs across industries.

Outlook

The future of Japan's TIM market is set for significant transformation. Ongoing research and technological advancements are likely to yield new materials that redefine thermal management in electronics and beyond. As Japan continues to lead in technological innovation, the TIM market is expected to offer substantial growth opportunities for investors and companies alike.

About Xiamen Jucheng Technology Co., Ltd.

Xiamen Jucheng Technology Co., Ltd. is a high-tech enterprise specializing in the R&D, production and sales of aluminum nitride (AlN) powder and AlN ceramic products. The company's core products include high-purity aluminum nitride powder, AlN ceramic substrates, AlN heat sinks and precision structural components, which are widely used in semiconductor packaging, 5G communications, new energy vehicles, power electronics, aerospace and other fields.

Juci Technology possesses advanced aluminum nitride powder synthesis technologies (such as carbothermal reduction method) and ceramic forming processes (including tape casting, dry pressing, and high-temperature sintering), ensuring its products exhibit excellent properties such as high thermal conductivity (170-200 W/mK), high insulation, and low thermal expansion. The company's AlN ceramic products have been successfully applied in high-end applications including IGBT modules, LED chip heat dissipation, and RF devices, contributing to the domestic substitution of imported materials.

Leveraging its independent R&D capabilities, the company continuously optimizes material performance and maintains close collaboration with upstream and downstream partners in the industrial chain. Committed to becoming a leading domestic aluminum nitride materials supplier, Juci Technology is driving the autonomous and controllable development of China's high-end electronic ceramic industry.

Media Contact:

Xiamen Juci Technology Co., Ltd.

Phone: +86 592 7080230

Email: miki_huang@chinajuci.com

Website: www.jucialnglobal.com