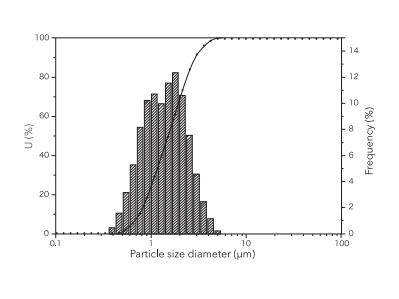

Faced with the wide variety of aluminum nitride powders on the market, how do you make the best choice? A common mistake when selecting aluminum nitride powder is focusing solely on purity while ignoring the particle size distribution. In fact, choosing the wrong particle size can lead to sintering difficulties, failure to meet thermal conductivity standards, or a significant increase in production costs. Particle size distribution often plays a decisive role in the selection of aluminum nitride powder.

First, we need to clarify the primary role aluminum nitride plays in our product, as this determines the general direction for selection.

1、Application: High Thermal Conductivity Ceramic Substrates / Structural Components

This is the most classic application for aluminum nitride, aiming to achieve a sintered body with high density and high thermal conductivity.

Primary Performance Indicators: Ultra-high thermal conductivity (>170 W/mK), high mechanical strength, high insulation.

Recommended Particle Size Distribution:

Strategy: Choose a "Bimodal Distribution"

Characteristics: Consists of a mixture of coarser and finer particles in specific proportions.

Advantages: Fine particles fill the voids between coarse particles, achieving very high green density and sintered density. This allows for high thermal conductivity and excellent mechanical strength at relatively low sintering temperatures. This is currently the most commonly used and reliable solution in the industry.

2、 Application: Thermal Interface Materials (As a Functional Filler)

In this case, aluminum nitride powder is dispersed as a filler in polymers (such as thermal grease, epoxy resin, plastics) and does not require sintering.

Primary Performance Indicators: High filling rate, high thermal conductivity, good rheology, low viscosity.

Recommended Particle Size Distribution:

Strategy: Pursuing High Filling & Flowability → Choose "Spherical or Near-Spherical Fine Powder"

Characteristics: The particle size distribution can be adjusted according to requirements.

Advantages: Fine particles provide a large specific surface area, enabling the formation of a denser thermal conduction pathway within the polymer. Spherical particles offer excellent flowability, allowing for higher packing density without significantly increasing the system's viscosity, which is beneficial for processes like potting and coating.

Advanced Strategy: A "bimodal" or "multimodal" distribution of fillers can also be used, where small particles fill the gaps between larger particles, further enhancing the density of the thermal network.

About Xiamen Juci Technology Co., LTD

Xiamen Juci Technology Co., Ltd. is a leading producer and supplier of high-performance aluminum nitride (AlN) powder. The company is based on independent research and development and large-scale production, aiming to provide customers with high-quality core materials of aluminum nitride. With a profound understanding and precise control of the preparation process, we ensure that every batch of AlN powder produced has a highly concentrated particle size distribution, excellent fluidity and sintering activity. These key features make our products an ideal source for thermal conductive fillers, AlN ceramic substrates and electronic packaging applications. Juci Technology is committed to becoming your strategic partner in enhancing thermal management efficiency and product reliability with stable and reliable products.

Media Contact:

Xiamen Juci Technology Co., Ltd.

Phone: +86 592 7080230

Email: miki_huang@chinajuci.com

Website: www.jucialnglobal.com