Xiamen Juci Technology Co., Ltd. presents its 150μm high-purity aluminum nitride (AlN) filler powder, a functional ceramic filler designed for high-performance thermally conductive composite materials. With key advantages including ultra-fine particle size (150 microns), high purity (≥99%), and low oxygen content, this product significantly enhances the thermal conductivity of polymer, metal, or ceramic matrix composites. It is widely used in electronic packaging, thermal interface materials (TIMs), high-power LED heat dissipation, and more.

Key Features:

1、Exceptional Thermal Conductivity

AlN boasts a theoretical thermal conductivity of 170-200 W/(m·K), over five times higher than conventional alumina fillers, dramatically improving the overall thermal efficiency of composite materials.

2、Precise Particle Size Distribution

D50: 150μm, uniform particle size, smooth surface, and excellent dispersibility ensure efficient thermal conductive network formation in the matrix.

3、High Purity & Low Oxygen Content

Purity ≥99%, oxygen content ≤1%, minimizing impurities' impact on dielectric properties and thermal conductivity, making it ideal for high-frequency electronic devices.

4、Superior Electrical Insulation

Volume resistivity >10¹⁴ Ω·cm, low dielectric constant (~8.8), suitable for high-insulation-demanding electronic packaging.

5、Strong Chemical Stability

High-temperature resistance (stable in air up to 1400°C), corrosion resistance, and excellent compatibility with epoxy resins, silicone gels, and other matrix materials.

Item No :

F-150Size :

150μmOrder(MOQ) :

1KGProduct Origin :

CHINAColor :

Gray-white

| Item | F-150 |

| D50 (μm) | 150 |

| D90(um) | 195 |

| Particle shape | Spherical |

| Specific surface area (m2/g) | 3.31 |

| Bulk density (g/cm3) | 1.8 |

| Tap density (g/cm3) | 2.0 |

Application :

Electronic Packaging: Thermal enhancement AlN filler for IC substrates and ceramic circuit boards (e.g., DPC, HTCC).

Thermal Interface Materials (TIMs): AlN filler in thermal greases and pads, reducing thermal contact resistance between chips and heat sinks.

High-Power Device Cooling: Heat dissipation for LED chips, 5G RF modules, and IGBT modules.

Specialty Ceramics: Used in high-thermal-conductivity AlN ceramic substrates or composites.

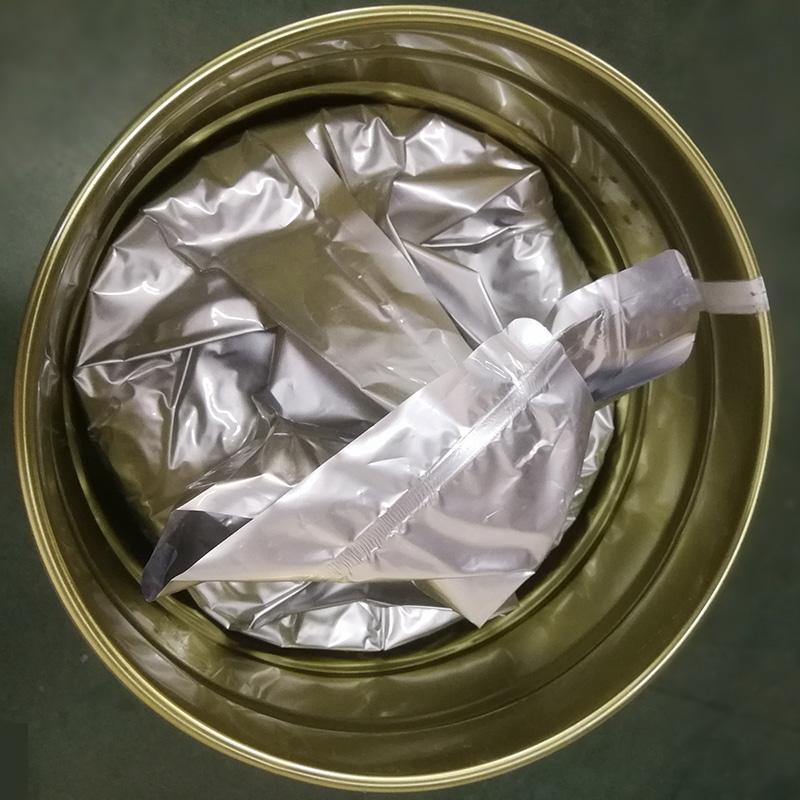

Package

10-20kg/bucket

Aluminum nitride filler is packed in aluminum foil bags filled with nitrogen and then in iron drums.

The advantages of Xiamen Juci Technology Co., Ltd.

As a leading aluminum nitride (AlN) manufacturer, we deliver superior ceramic solutions with:

1、 High-Performance Powders

≥99% purity with ≤1% oxygen content

2、Controlled particle size (D50≈120μm)

Excellent thermal conductivity (170-200 W/m·K)

3、Customized Solutions

Tailored formulations for electronics & energy applications

Surface modification options available

4、Reliable Production

Strict ISO 9001 quality control

Stable global supply with consistent quality

5、Technical Expertise

Continuous R&D for advanced thermal management

Application-specific technical support

We combine precision manufacturing with innovative material science to power your thermal solutions.

Company and Laboratory

Media Contact:

Xiamen Juci Technology Co., Ltd.

Phone: +86 592 7080230

Email: miki_huang@chinajuci.com

Website: www.jucialnglobal.com

Tags :