Xiamen Juceri Technology's 120μm Aluminum Nitride (AlN) filler powder is a high-purity, high-thermal-conductivity ceramic powder material, specifically designed for high-performance thermally conductive composites, electronic packaging, thermal interface materials (TIM), and high-thermal-conductivity plastics/rubbers. With its uniform particle size distribution (D50≈120μm) and excellent chemical stability, it significantly enhances the thermal conductivity of matrix materials while maintaining superior electrical insulation and mechanical strength.

Key Features:

1、Ultra-High Thermal Conductivity

Theoretical thermal conductivity of 170-200 W/(m·K), effectively improving the heat dissipation efficiency of composite materials.

2、Precise Particle Size Control

Median particle size (D50) of 120μm with uniform distribution, ensuring easy dispersion and strong compatibility with resin/polymer matrices.

3、High Purity & Low Oxygen Content

Purity ≥99%, oxygen content ≤1%, minimizing the impact of impurities on dielectric properties and thermal conductivity.

4、Excellent Insulation Performance

Volume resistivity >10¹⁴ Ω·cm, suitable for electronic applications requiring high insulation.

5、Chemical Stability

Resistant to high temperatures and corrosion, maintaining stable performance in high-temperature or humid environments.

6、Surface Modifiability

Can be treated with silane coupling agents or other surface modifications upon request to enhance interfacial bonding with the matrix.

Item No :

F-120Size :

120μmOrder(MOQ) :

1KGProduct Origin :

CHINAColor :

Gray-white

| Item | F-120 |

| D50 (μm) | 120 |

| D90(um) | 160 |

| Particle shape | Spherical |

| Specific surface area (m2/g) | 3.31 |

| Bulk density (g/cm3) | 1.8 |

| Tap density (g/cm3) | 2.0 |

Application :

Typical Applications Electronic Packaging: IC substrates, LED heat dissipation modules, power device packaging.

Thermal Interface Materials (TIM): Thermal greases, thermal pads, thermal adhesives, etc.

High-Thermal-Conductivity Composites: Thermally conductive plastics, thermally conductive rubbers, ceramic-based composites.

Aerospace: Heat dissipation coatings for high-temperature components, thermal management material for electronic devices.

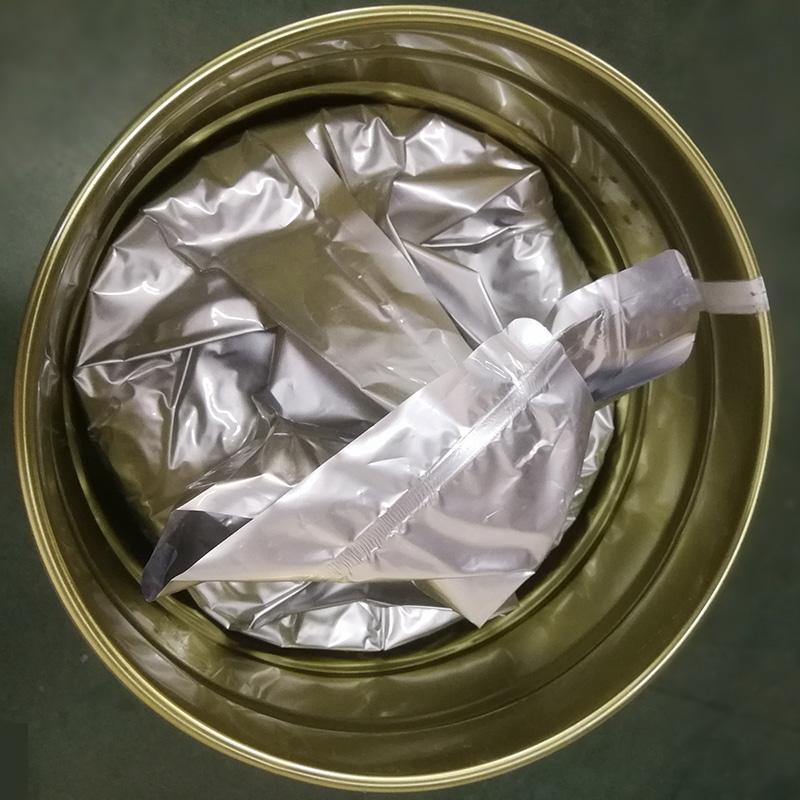

Package

10-20kg/bucket

Aluminum nitride filler is packed in aluminum foil bags filled with nitrogen and then in iron drums.

The advantages of Xiamen Juci Technology Co., Ltd.

Xiamen Juci Technology Co., Ltd. is a leading AlN manufacturer specializing in high-performance ceramic materials, particularly aluminum nitride (AlN) powders and related products. Our company stands out in the industry due to the following key advantages:

①Advanced Technical Expertise – We possess deep knowledge in ceramic material science and engineering, enabling us to develop high-purity, high-thermal-conductivity AlN powders that meet stringent industry requirements.

②Precision Manufacturing – Our production processes ensure strict control over particle size distribution (e.g., D50 ≈ 120μm), purity (≥99%), and oxygen content (≤1%), guaranteeing consistent product quality.

③Custom Solutions – We offer tailored material formulations, including surface-modified powders, to meet specific application needs in electronics, aerospace, and energy sectors.

④Reliable Supply Chain – With robust production capacity and efficient logistics, we ensure stable, on-time delivery to global customers.

⑤Quality Assurance – Our products undergo rigorous testing and comply with international standards, including ISO 9001 certification.

⑥Innovation-Driven – We continuously invest in R&D to enhance material performance and expand applications in next-generation thermal management solutions.

By combining cutting-edge technology with customer-focused service, Juci Technology delivers superior ceramic materials that drive innovation across industries.

Company and Laboratory

Media Contact:

Xiamen Juci Technology Co., Ltd.

Phone: +86 592 7080230

Email: miki_huang@chinajuci.com

Website: www.jucialnglobal.com

Tags :