If you are searching for high-performance aluminum nitride (AlN) powder, the technical parameter "particle size distribution" is an absolutely essential factor you cannot overlook. It is not just a row of complex numbers on a data sheet but a hidden code that determines the success or failure of your final product.

So, what exactly is the particle size distribution of aluminum nitride powder? And how does it affect your production process and product performance? Let’s uncover the mystery together.

1. In Simple Terms, What Is Particle Size Distribution?

Imagine a bag of rice containing both whole grains and some broken bits. The same applies to aluminum nitride powder—it does not consist of particles all of the same size.

Particle size distribution is a scientific method to describe the proportion of particles of different sizes in this "bag of aluminum nitride powder." It tells us whether the powder is "uniform" or "varied in size."

Key metrics typically include:

D50: This is a median value. It indicates that 50% of the particles in the sample have a diameter smaller than this value, and 50% are larger. It is a core metric for measuring the "average fineness" of the powder.

D10 and D90: These represent the particle diameters below which 10% and 90% of the sample particles lie, respectively. They define the "range" of particle sizes in the powder.

Span: Calculated as (D90 - D10) / D50. A smaller Span value indicates more uniform particle sizes and a more concentrated distribution, while a larger Span value suggests greater variation in particle sizes and a wider distribution.

2. Why Is Particle Size Distribution So Important?

Particle size distribution directly affects the physical and chemical properties of the powder, thereby influencing every step from processing to the final product.

Impact on Sintering Density

Fine particles: More active and easier to fuse at high temperatures, contributing to high-density sintering at lower temperatures, saving energy.

Optimal combination: Using a "bimodal distribution" (i.e., intentionally mixing particles of two different sizes) is like combining sand and stones—small particles perfectly fill the gaps between larger ones, achieving the highest packing density and resulting in a denser, stronger product after sintering.

Decisive Influence on Thermal Conductivity

The core value of aluminum nitride lies in its exceptional thermal conductivity. Heat transfer is most hindered by "obstacles."

Pores are obstacles: Poor particle size distribution can lead to pores after sintering, severely reducing thermal efficiency.

Grain boundaries are also obstacles: Uniform and appropriately coarse particles help form larger crystal grains, reducing the "walls" (grain boundaries) between crystals. This allows heat (phonons) to flow unimpeded, maximizing thermal conductivity.

Adaptability to Production Processes

Tape casting: Requires ultra-fine powder with uniform particles (small Span value) to prepare stable, non-laminating slurry, ultimately yielding smooth and flat ceramic substrates.

Die pressing: Tolerates a wider range of particle size distributions but still requires a reasonable distribution to ensure filling rate and green strength.

About Xiamen Juci Technology Co., LTD

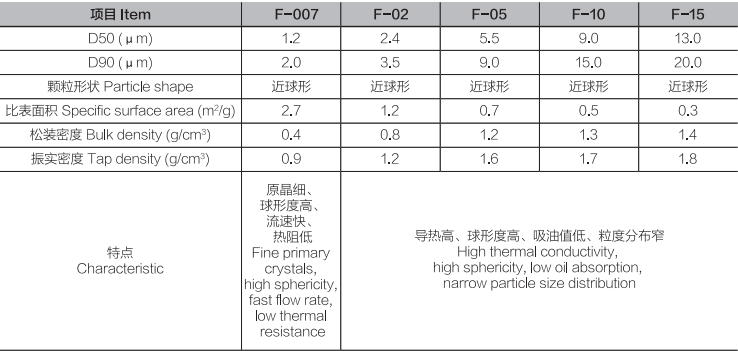

Xiamen Juci Technology Co., Ltd. specializes in the R&D and production of high-performance aluminum nitride (AlN) powders. Leveraging advanced preparation techniques and stringent quality control, we precisely tailor the particle size distribution of our AlN powders to ensure high uniformity and consistency. Our products feature a concentrated and narrow particle size distribution, which provides excellent flowability and sintering activity, making them ideal for applications such as thermal conductive AlN fillers, AlN ceramic substrates, and electronic packaging. We are your key material partner in enhancing the thermal performance and reliability of your products.

Media Contact:

Xiamen Juci Technology Co., Ltd.

Phone: +86 592 7080230

Email: miki_huang@chinajuci.com

Website: www.jucialnglobal.com